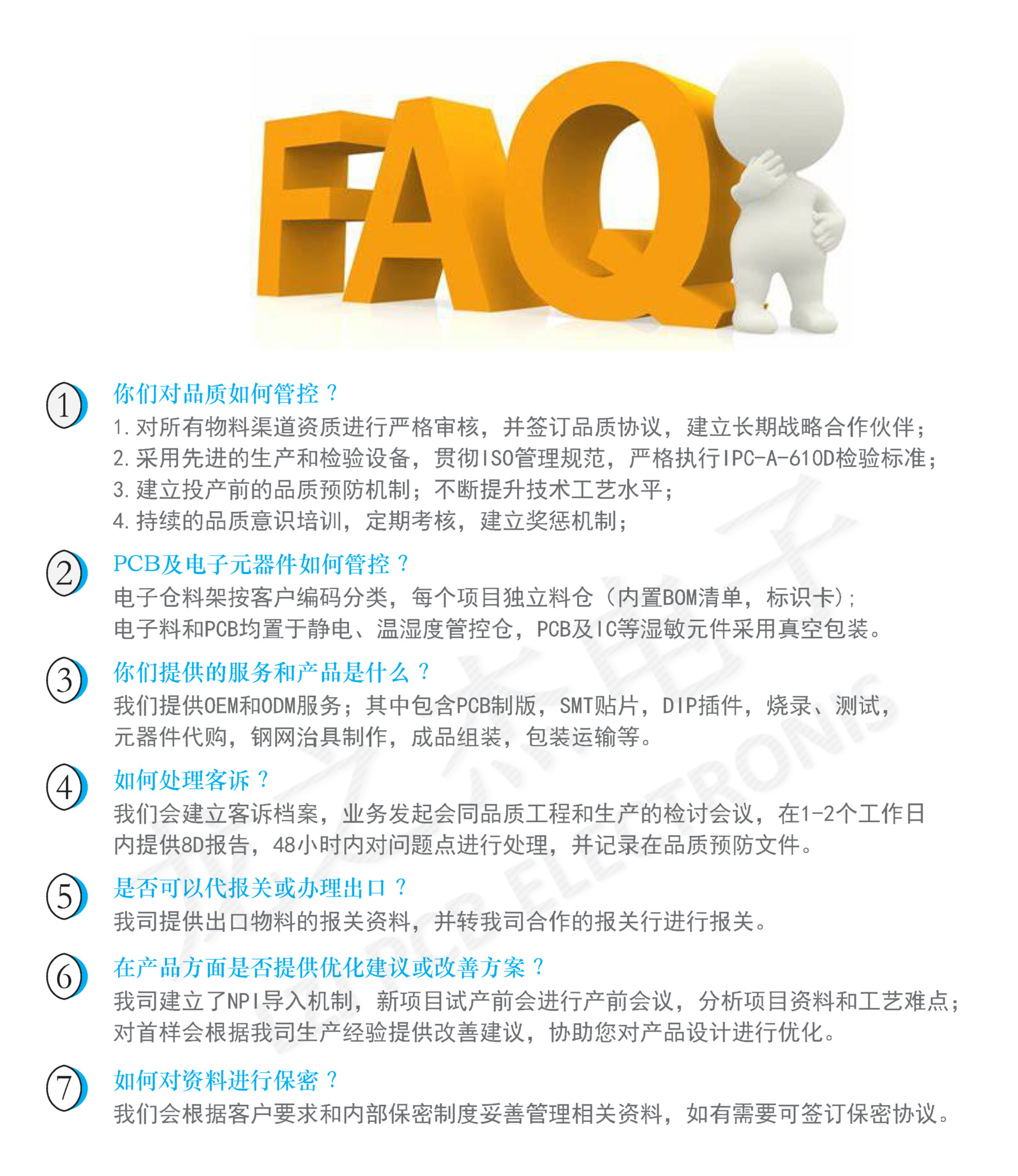

Perfect quality certification system

Factory through DFM manufacturability inspection, NPI new product introduction meeting, IQC incoming inspection, IPQC process inspection, OQA factory inspection and other links of lean improvement, So that we can successfully obtain ISO9001:2015 quality management system certification, ISO13485 medical certification, IATF16949 certification, SGS certification and so on. Quality and service are the fundamental reasons for medium and large customers to choose us for a long time.

Lean process capabilities make your choice worry-free

Lean manufacturing advantages allow us to have strong capacity and process capabilities to better serve demanding customers. The new online ERP system, MES manufacturing execution system, bar code management and traceability system aims to establish an intelligent and flexible patch assembly production line, and achieve lean management of production process traceability, quality analysis and early warning, test data cloud storage, product failure analysis and engineering process improvement.

| x 4 SMT production lines |

SPI solder paste detector |

| DIP production line x 2 pieces |

FAI first piece detector |

| ICT/FCT test lines x 2 |

AOI Online/offline optical inspection

|

| Three anti-paint spraying lines x 1 |

X-Ray detection

|

| Finished product assembly lines x 2 |

BGA repair table

|

| Mounter: YAMAHA YSM10 / YSM20R |

Program-controlled baking box

|

| Mounting accuracy: 01005 |

Insulation resistance tester

|

| BGA ball distance: 0.20mm |

Withstand voltage tester

|

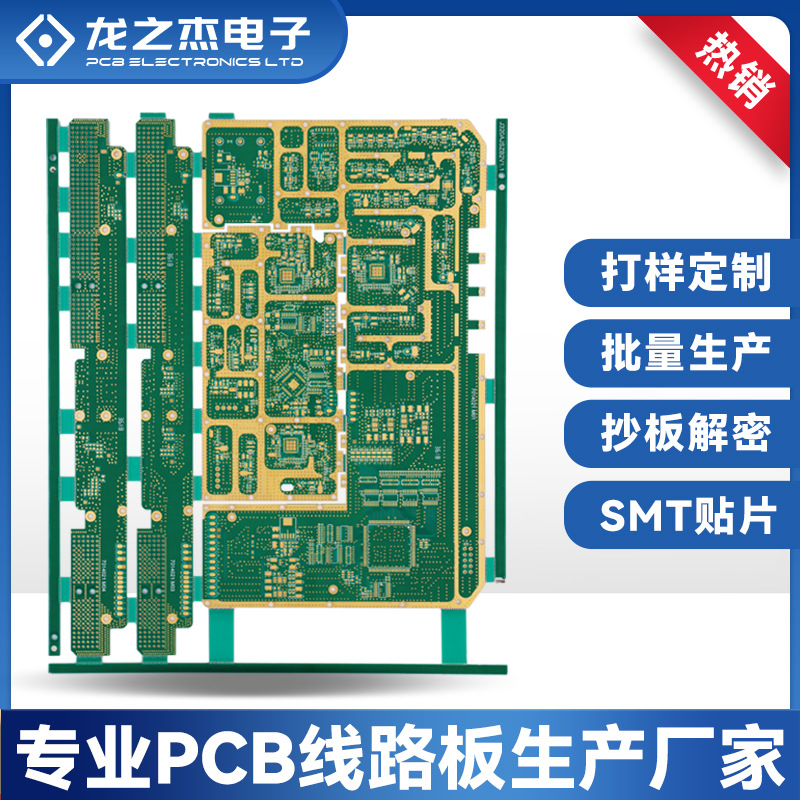

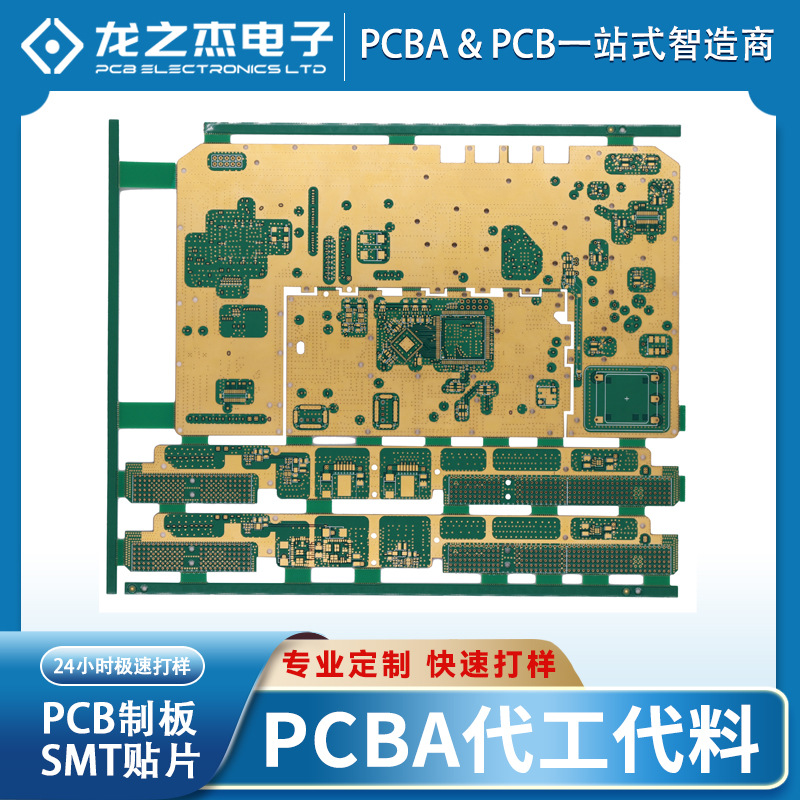

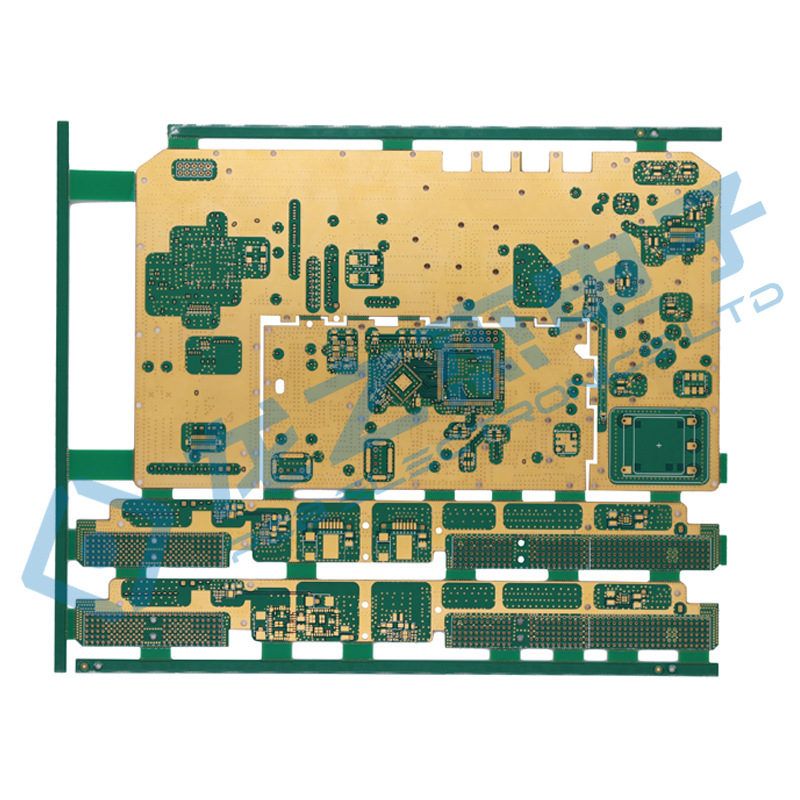

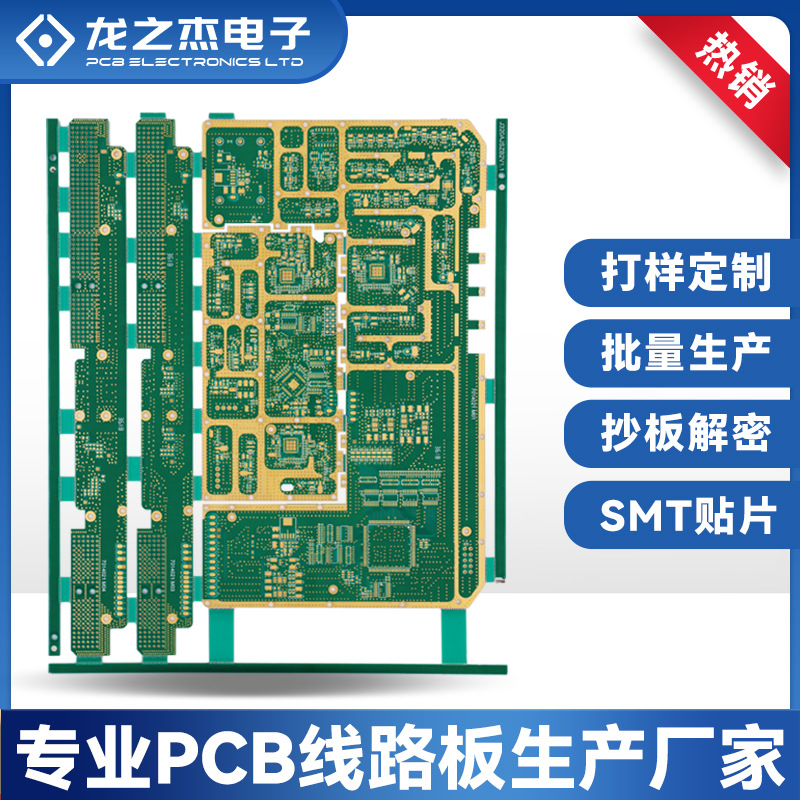

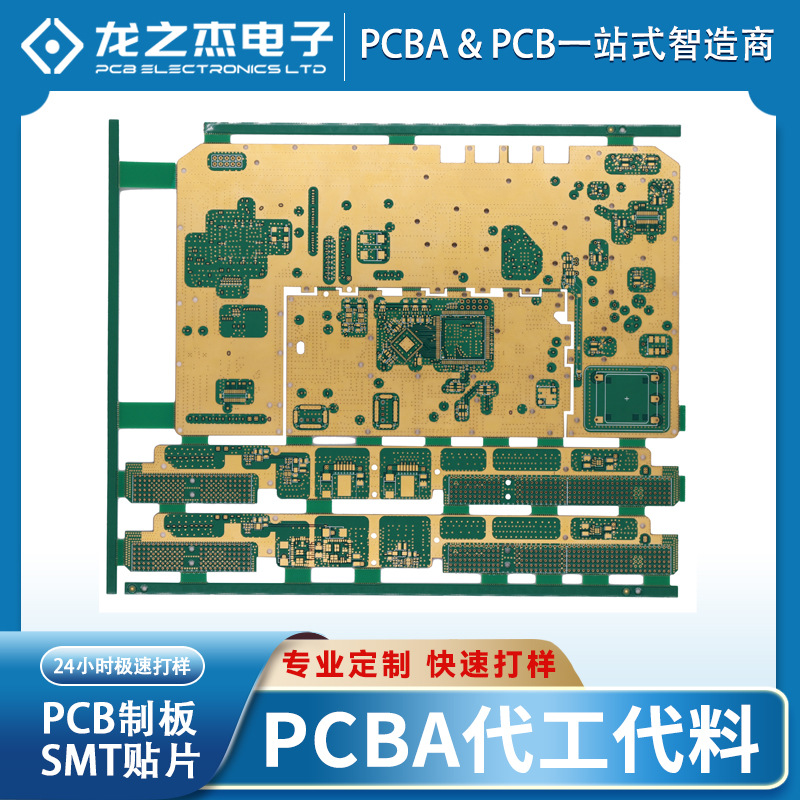

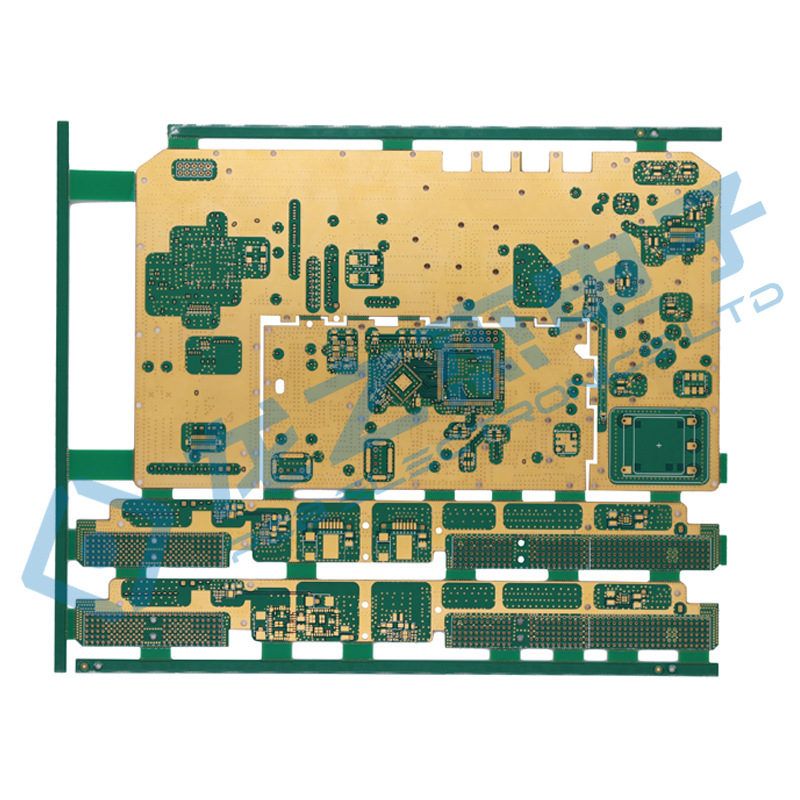

| PCB: 1-40 layers, blind hole, impedance, thick copper, HDI |

Temperature and humidity control box

|

| Test rack: Homemade |

Electronic load |

Made of the heart

Our high quality EMS electronics manufacturing services are serving a wide range of industries for a long time, with many successful cases.